Reginald Gray is the visionary force behind PersonalInjuryJustice. A seasoned lawyer with over two decades of experience in personal injury law, Reginald's profound understanding of...Read more

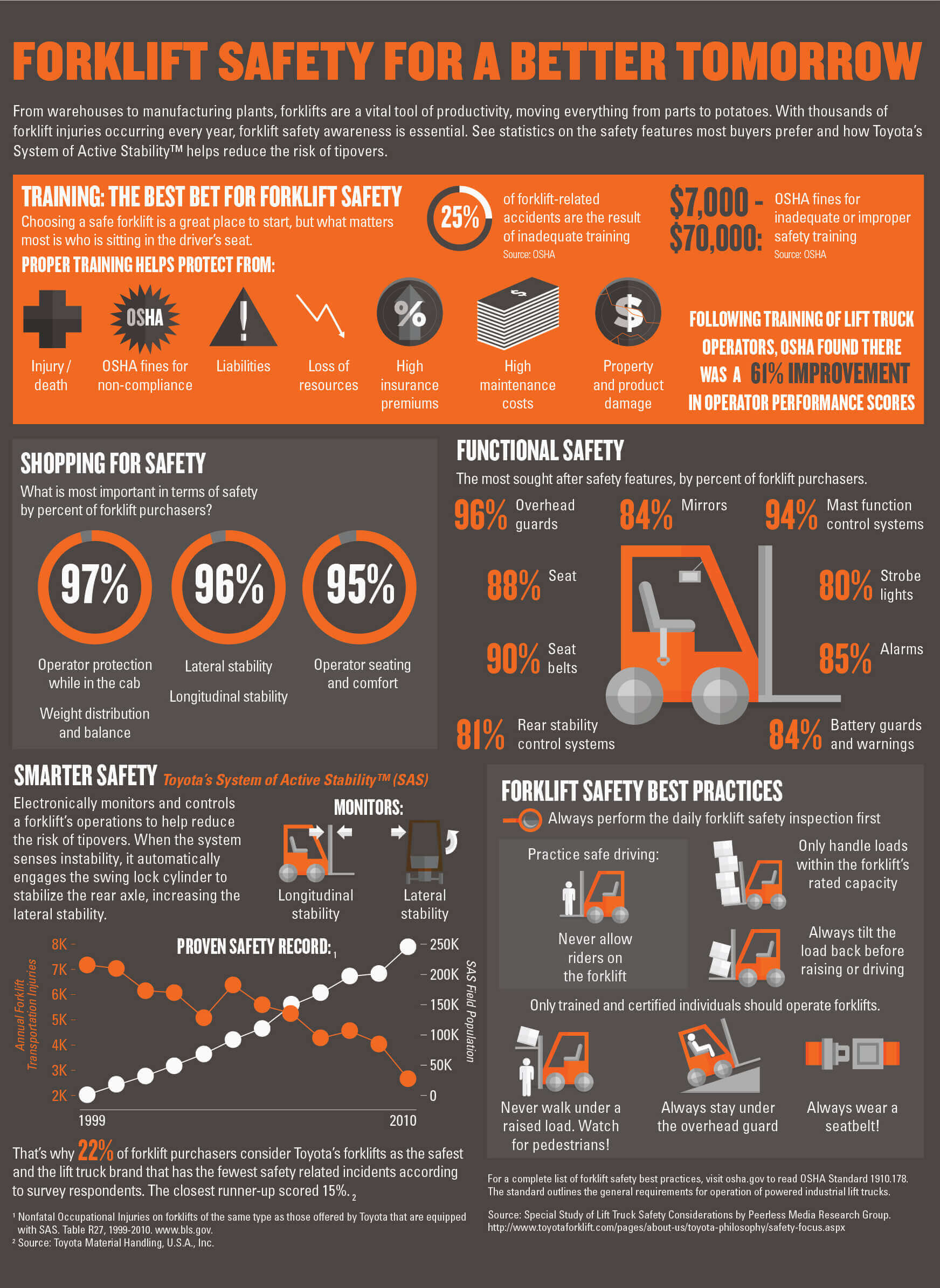

Lift trucks are essential equipment in the material handling industry, but they can also be dangerous if not operated with care. Unfortunately, lift truck accidents are not uncommon, and they can result in serious injuries, property damage, and even fatalities.

So, what is the number one cause of lift truck accidents? Is it operator error, equipment malfunction, or something else entirely? Let’s explore this topic in-depth and uncover the root of lift truck accidents.

The number one cause of lift truck accidents is operator error. Failure to follow proper safety procedures, lack of training, and distractions can all lead to accidents. It’s essential to ensure that operators are properly trained and follow safety guidelines to prevent accidents.

Contents

- What is the Number One Cause of Lift Truck Accidents?

- Frequently Asked Questions

- What are some common causes of lift truck accidents?

- How can lift truck accidents be prevented?

- What are the consequences of lift truck accidents?

- What should I do if I am involved in a lift truck accident?

- Who is responsible for lift truck accidents?

- HOW TO What is the most common type of lift truck accidents?😱

What is the Number One Cause of Lift Truck Accidents?

Lift trucks, also known as forklifts, are essential equipment in warehouses, distribution centers, and other industrial settings. They are designed to move heavy loads, making tasks easier and efficient. However, lift trucks can pose dangers to operators and pedestrians if not used correctly. Every year, thousands of lift truck accidents occur, resulting in injuries, fatalities, and property damage. The number one cause of lift truck accidents is operator error.

1. Lack of Training

The Occupational Safety and Health Administration (OSHA) requires employers to provide training to lift truck operators before they start operating the equipment. However, some employers fail to provide adequate training, or operators do not take the training seriously. Lift truck operators must be trained to understand the equipment’s capabilities and limitations, the importance of load stability, safe operating procedures, and how to handle emergency situations. Lack of training can lead to accidents, injuries, and fatalities.

2. Overloading

Lift trucks are designed to handle specific loads based on their capacity rating. Overloading the lift truck can lead to instability, tipping over, and falling loads. Operators must know the lift truck’s capacity rating and the weight of the load they are carrying. They should also ensure the load is evenly distributed and secured before moving it.

3. Speeding

Lift truck operators must adhere to speed limits and drive at a safe speed. Speeding can cause accidents, especially when turning corners or carrying loads. Operators should slow down and sound the horn when approaching intersections or blind corners.

4. Distracted Driving

Distracted driving is a significant cause of lift truck accidents. Operators must focus on the task at hand and avoid distractions such as texting, using a phone, or eating while operating the lift truck. They should also be aware of their surroundings, including pedestrians and other vehicles.

5. Improper Maintenance

Lift trucks must be well-maintained to ensure they are safe to operate. Employers must have a maintenance program in place to inspect and repair the equipment regularly. Lift truck operators should also conduct pre-shift inspections to identify any defects or issues that need attention.

6. Improper Use of Attachments

Lift truck attachments, such as clamps and forks, can increase the equipment’s versatility. However, improper use of attachments can cause accidents. Operators must use the correct attachment for the load they are carrying and ensure the attachment is securely fastened.

7. Driving on Uneven Surfaces

Lift trucks are designed to operate on smooth surfaces. Driving on uneven surfaces, such as ramps or potholes, can cause the equipment to tip over or lose control. Operators must avoid uneven surfaces or drive slowly and carefully on them.

8. Poor Visibility

Poor visibility is another cause of lift truck accidents. Operators must have an unobstructed view of their surroundings, including pedestrians, other vehicles, and obstacles. They should use mirrors, cameras, or spotters to improve visibility.

9. Fatigue

Fatigue can impair an operator’s judgment and reaction time, leading to accidents. Employers must ensure lift truck operators have adequate rest breaks and do not work extended hours. Operators should also take breaks when they feel tired or stressed.

10. Lack of Communication

Effective communication is essential in preventing lift truck accidents. Employers must have clear policies and procedures for lift truck operations, including communication protocols. Operators should communicate with each other, pedestrians, and other vehicles to avoid accidents.

In conclusion, operator error is the number one cause of lift truck accidents. Employers must provide adequate training, ensure equipment is well-maintained, and have clear policies and procedures in place. Lift truck operators must adhere to safe operating procedures, avoid distractions, and communicate effectively to prevent accidents. By addressing the causes of lift truck accidents, employers can create a safer working environment and prevent injuries and fatalities.

Frequently Asked Questions

What are some common causes of lift truck accidents?

Lift truck accidents can occur due to various reasons, but some of the most common causes include operator error, lack of training, poor maintenance, and improper loading. Operators may make mistakes such as driving too fast, ignoring safety protocols, or not using seatbelts. Lack of training can result in inexperienced operators who may not know how to handle the equipment properly. Poor maintenance can lead to malfunctions and equipment failure. Improper loading can cause the load to shift, resulting in a loss of stability and potentially causing an accident.

How can lift truck accidents be prevented?

There are several ways to prevent lift truck accidents. Employers can ensure that operators receive proper training and certification before operating the equipment. Regular maintenance and inspections can detect and address any potential issues before they become a problem. Employers can also implement safety protocols and procedures, such as wearing seatbelts, following speed limits, and avoiding distractions. Additionally, proper loading practices can help prevent accidents.

What are the consequences of lift truck accidents?

Lift truck accidents can result in serious consequences, including injuries, fatalities, property damage, and financial loss. Operators and pedestrians can suffer injuries ranging from minor cuts and bruises to more severe injuries such as broken bones or head trauma. In extreme cases, lift truck accidents can result in fatalities. Property damage can occur if the lift truck collides with equipment, buildings, or other objects. The financial impact can include medical costs, lost productivity, and legal fees.

What should I do if I am involved in a lift truck accident?

If you are involved in a lift truck accident, the first step is to seek medical attention if necessary. Notify your supervisor or manager and complete an incident report. Cooperate with any investigations conducted by your employer or regulatory authorities. It is important to document the details of the accident, including any witnesses, and take photographs if possible. If you are injured, you may need to file a workers’ compensation claim or seek legal advice.

Who is responsible for lift truck accidents?

Responsibility for lift truck accidents can vary depending on the circumstances. In general, employers have a responsibility to provide a safe work environment and ensure that employees receive proper training and equipment. Operators have a responsibility to follow safety protocols and operate the equipment responsibly. Manufacturers have a responsibility to design and produce equipment that is safe and reliable. Ultimately, determining responsibility for a lift truck accident may require an investigation to determine the cause and any contributing factors.

HOW TO What is the most common type of lift truck accidents?😱

In conclusion, the number one cause of lift truck accidents is human error. From lack of training to distractions while operating the vehicle, there are a multitude of ways that human error can lead to accidents. It is imperative that employers prioritize proper training and safety protocols to ensure that their workers are equipped to operate lift trucks safely. Additionally, workers must take responsibility for their own actions and avoid distractions while operating these machines.

Overall, reducing lift truck accidents requires a joint effort from both employers and employees. By working together to prioritize safety and minimize human error, we can ensure that these powerful vehicles are operated responsibly and accidents are minimized. It’s time to take lift truck safety seriously and make it a top priority in the workplace.

Reginald Gray is the visionary force behind PersonalInjuryJustice. A seasoned lawyer with over two decades of experience in personal injury law, Reginald's profound understanding of the legal landscape and his deep empathy for victims inspired the creation of PersonalInjuryJustice. His only mission is to ensure victims have easy access to comprehensive, authentic information to assist them in their fight for justice. As Chief Editor, he rigorously ensures our content's accuracy, reliability, and pertinence.

More Posts